Business Intelligence Tools to Track Production: Optimizing Manufacturing Efficiency

In the fast-paced world of manufacturing, staying ahead of the curve requires more than just hard work. It demands smart work. This means leveraging the power of data. This is where Business Intelligence (BI) tools come into play. These tools provide the insights needed to track production. They help to optimize efficiency, and ultimately, boost profitability. This article delves into the world of BI tools. It explores their crucial role in modern production environments.

The manufacturing landscape is constantly evolving. Companies face pressure to reduce costs. They must also improve product quality and streamline operations. Traditional methods of data analysis often fall short. They struggle to keep pace with the volume and complexity of modern production data. BI tools bridge this gap. They transform raw data into actionable intelligence. This enables manufacturers to make informed decisions. This is crucial for optimizing production.

The Core Benefits of Using BI Tools for Production Tracking

Implementing BI tools offers a multitude of benefits for production tracking. These advantages go beyond simply monitoring output. They provide a holistic view of the entire manufacturing process. This allows for continuous improvement and strategic decision-making. Some core benefits include:

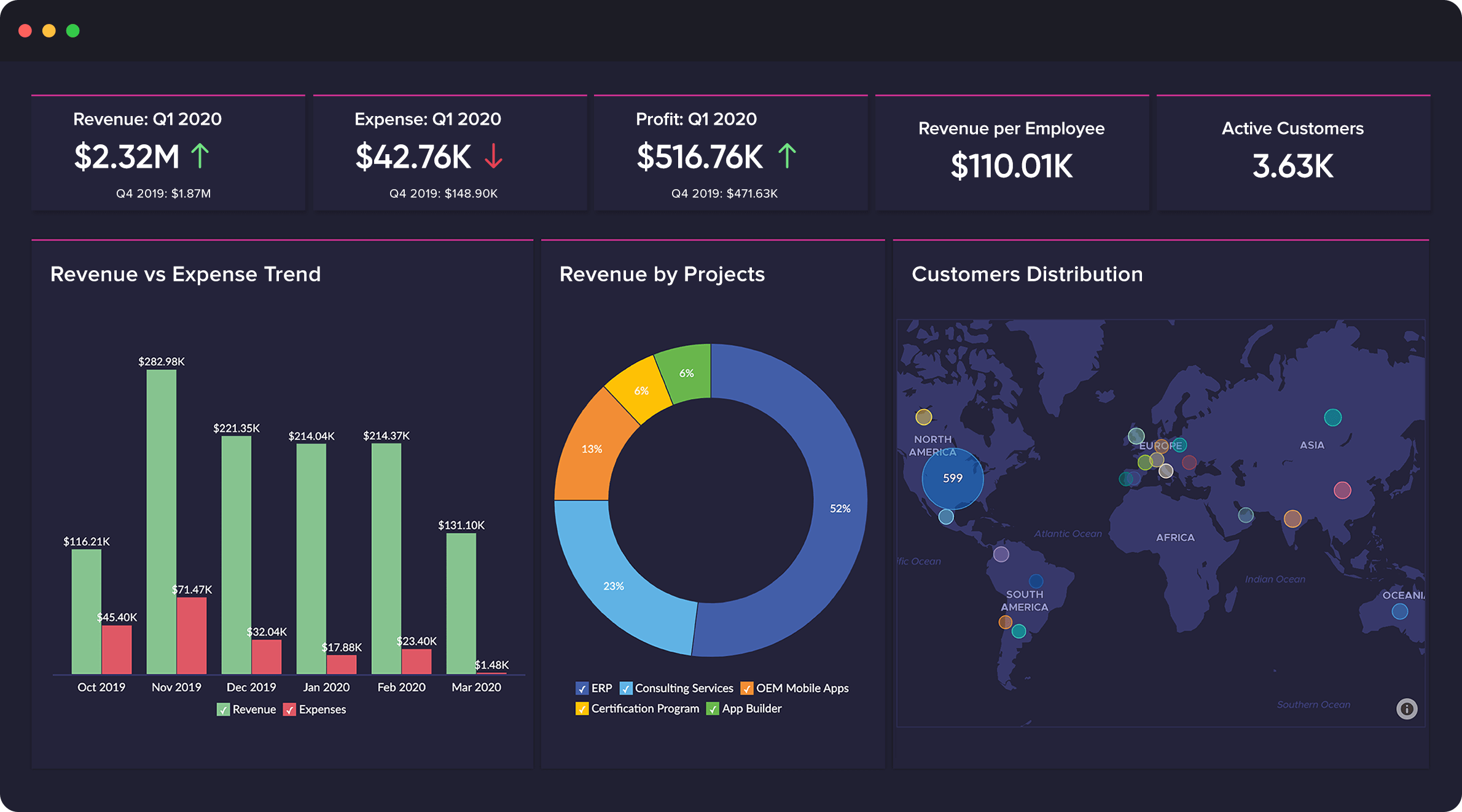

- Enhanced Visibility: BI tools provide real-time dashboards. These dashboards offer a clear view of production performance. They show key metrics such as output, downtime, and material usage.

- Improved Efficiency: By analyzing data, BI tools identify bottlenecks and inefficiencies. This allows manufacturers to optimize processes and reduce waste.

- Data-Driven Decision Making: Instead of relying on gut feelings, decisions are based on concrete data. This leads to more accurate and effective strategies.

- Cost Reduction: By identifying areas for improvement, BI tools help reduce costs. They can optimize resource allocation and minimize waste.

- Predictive Maintenance: Some BI tools incorporate predictive analytics. They can forecast equipment failures. This allows for proactive maintenance and reduces downtime.

Key Features to Look for in Production Tracking BI Tools

Not all BI tools are created equal. Choosing the right tool is crucial. It should meet the specific needs of a manufacturing operation. Several key features are essential for effective production tracking. These include:

- Real-Time Data Integration: The tool should be able to collect and process data in real-time. This ensures that users have access to the most up-to-date information.

- Customizable Dashboards: Dashboards should be customizable. They should allow users to visualize the metrics that are most important to them.

- Advanced Analytics: The tool should offer advanced analytics capabilities. This includes statistical analysis, predictive modeling, and data mining.

- Reporting Capabilities: Robust reporting features are essential. They allow users to generate reports. They can share insights with stakeholders.

- Mobile Accessibility: The ability to access data and dashboards on mobile devices is increasingly important. It provides flexibility and convenience.

Top Business Intelligence Tools for Production Tracking

Several BI tools stand out as leaders in the production tracking space. These tools offer a comprehensive suite of features. They can help manufacturers optimize their operations. Here are some of the most popular and effective options:

Tableau

Tableau is a widely used BI tool. It is known for its user-friendly interface and powerful visualization capabilities. It allows users to easily create interactive dashboards and reports. It is ideal for tracking production metrics. It also provides insights into performance.

Power BI

Microsoft Power BI is another popular choice. It integrates seamlessly with other Microsoft products. It offers a wide range of data connectivity options. It is a cost-effective solution for many manufacturing businesses. Power BI empowers users to track production. It also offers advanced analytics.

Qlik Sense

Qlik Sense is a self-service BI platform. It is designed for data discovery and analysis. It offers an associative data model. This allows users to explore data in a more intuitive way. It is excellent for uncovering hidden insights. It is also great for tracking production.

Sisense

Sisense is a BI platform. It is known for its ability to handle large datasets. It provides fast and accurate insights. It is well-suited for complex manufacturing environments. It helps businesses to track production effectively.

SAP Analytics Cloud

SAP Analytics Cloud is a cloud-based BI solution. It integrates with SAP systems. It is designed for enterprise-level organizations. It offers advanced analytics and planning capabilities. It is helpful for tracking production and improving efficiency.

Implementing BI Tools: A Step-by-Step Guide

Implementing BI tools for production tracking requires a strategic approach. A well-planned implementation ensures a successful outcome. Here is a step-by-step guide to help you get started:

- Define Your Goals: Identify the specific goals you want to achieve with BI. This may include reducing downtime. It could also mean improving output.

- Assess Your Data: Evaluate the data sources you have available. Determine what data you need to collect.

- Choose the Right Tool: Select a BI tool that meets your specific needs. Consider factors such as features, cost, and ease of use.

- Integrate Your Data: Connect your data sources to the BI tool. Ensure that data is being collected and processed correctly.

- Create Dashboards and Reports: Design dashboards and reports. These will visualize your key performance indicators (KPIs).

- Train Your Team: Provide training to your team on how to use the BI tool. This ensures they can effectively analyze data.

- Monitor and Optimize: Continuously monitor your production data. Make adjustments to your processes as needed.

Real-World Examples of Production Tracking Success

Many manufacturers have experienced significant improvements. They have achieved this through the use of BI tools. Here are a few real-world examples:

- Reduced Downtime: A manufacturing plant implemented a BI tool. They used it to analyze machine data. They identified patterns leading to equipment failures. They implemented a predictive maintenance program. This resulted in a 20% reduction in downtime.

- Improved Efficiency: A company used a BI tool to track its production line. They identified a bottleneck in the assembly process. They optimized the process. This increased throughput by 15%.

- Cost Savings: A manufacturer used a BI tool to analyze material usage. They identified areas where materials were being wasted. They implemented changes to reduce waste. This resulted in a 10% reduction in material costs.

The Future of BI Tools in Production

The future of BI tools in production is bright. Advancements in technology will continue to shape the industry. Several trends are emerging:

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML will play a larger role. They will automate data analysis. They will provide more advanced insights.

- Cloud-Based Solutions: Cloud-based BI tools will become even more popular. They offer scalability and flexibility.

- Integration with IoT: The integration of BI tools with the Internet of Things (IoT) will increase. This will provide real-time data from connected devices.

- Focus on Data Democratization: BI tools will become more accessible. This will empower more employees. They will be able to analyze data.

Business intelligence tools are essential for modern manufacturing. They provide the insights needed to track production effectively. They also help optimize efficiency and drive profitability. By implementing the right BI tools, manufacturers can gain a competitive edge. They can improve their processes. They can also make data-driven decisions. This will ensure their success in an increasingly competitive market. The insights gained from these tools are invaluable for tracking production. They offer a pathway to continuous improvement.

The ability to track production in real-time is a game-changer. It empowers manufacturers to respond quickly to issues. It also helps to optimize their operations. Implementing business intelligence tools is an investment. It is an investment in the future of a manufacturing business. It ensures sustainability and growth. It also provides the tools needed to navigate the complexities of modern production. The insights gained from these tools are essential for tracking production. They provide a clear path to success.

The benefits of using business intelligence tools are clear. They offer a comprehensive view of the entire manufacturing process. This allows for continuous improvement and strategic decision-making. By embracing these tools, manufacturers can unlock their full potential. They can also achieve operational excellence. They can also improve their bottom line. The insights gained from these tools are critical for tracking production. They offer a clear path to operational success.

By leveraging business intelligence tools, manufacturers can transform raw data into actionable insights. They can optimize production processes. They can also drive significant improvements in efficiency. This includes reducing costs and improving overall performance. The insights gained from these tools are invaluable for tracking production. They offer a clear path to success. [See also: Related Article Titles]